The main components of electrophoretic coating line:

1、 Pretreatment system:The workpiece is pretreated by cleaning, degreasing and derusting to improve the adhesion of the coating.

- Remove grease and other impurities from the surface of the workpiece.

- Form a phosphating film on the surface of the workpiece to enhance the adhesion of the coating.

2、 Electrophoresis system:All parts collaborate to achieve efficient and uniform electrophoretic coating.

- The electrophoresis tank is the main location for electrophoretic coating;

- Circulating stirring ensures uniformity and prevents sedimentation;

- Ultrafiltration filters impurities and recovers them;

- The power system provides stable DC power supply

3、Drying system:Dry the coating to cure it.

After electrophoretic coating, clean the residual electrophoretic paint on the surface of the workpiece and enter the drying oven for drying and solidification.

Customer installation site:Comprehensive tracking service

Customer case study:Products for various industries

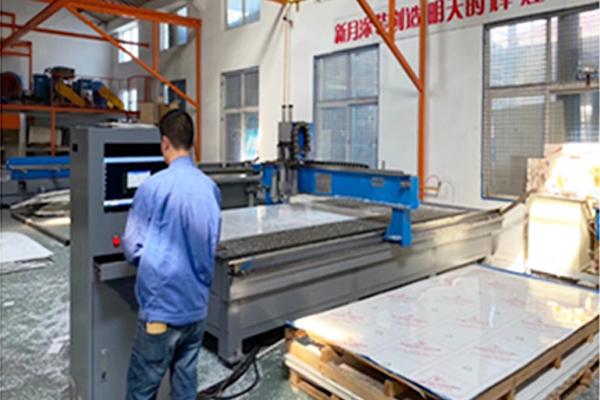

Factory floor view:Crafted with meticulous care to create fine products

Customer recognition of our work:Excellent service、Quality is good

Qualifications and Certificates:profession、strength、integrity

Contactez-nous:Our professional foreign trade team is at your service

Téléphone:+86 17802529388

WhatsAPP:008617802529388

Courriel:tzxinyue@gmail.com

Chine-XinYue Spraying Equipment co., ltd

Chine-XinYue Spraying Equipment co., ltd

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.